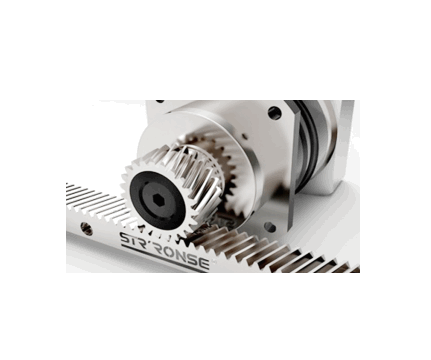

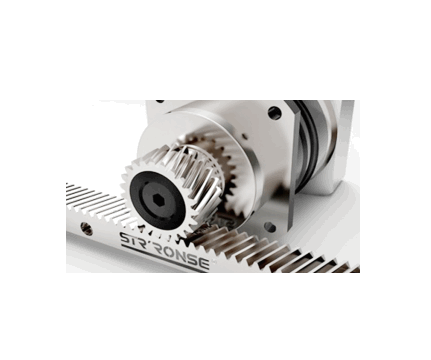

STRRONSE is an enterprise specializing in the design, development and production of rack and pinion. During the development of the company, it has always adhered to the requirements of high-quality production management, applied the world's high-priced production equipment, continuously improved technology, and improved quality and efficiency.

Racks category

1.Teeth surface high-precision grinding rack DIN6

Spur rack DIN6 / Helical rack DIN6

Teeth Grinding Precision:DIN6

Modulus:1.5,2,3,4,5,6,8

Material:C45

Hardness:HRC50-55

Heat Treatment:Teeth induction hardening

More cost-effective DIN6 rack, high-precision, high-rigidity rack with ground teeth surface and side surface.

2.Teeth surface high-precision grinding rack DIN6A

Spur rack DIN6S / Helical rack DIN6S

Teeth Grinding Precision:DIN6A

Modulus:1.5,2,3,4,5,6,8

Material:C45

Hardness:HRC50-55

Heat Treatment:Teeth induction hardening

The teeth surface and side surface are ground, and the product has high wear resistance after quenching treatment, and the teeth surface precision is high.

3.Precision milling quenched and tempered rack DIN8

Spur rack DIN8 / Helical rack DIN8

Teeth Grinding Precision:DIN8

Modulus:2,3,4,5

Material:C45

Hardness:HRC24-27

Heat Treatment:quenching and tempering

The side positioning surface of the rack has been ground, and the product has high precision, which can ensure the basic accuracy of the equipment operation. The material has been quenched and tempered to increase its wear resistance.

4.Precision milling high frequency quenching rack DIN9

Spur rack DIN9 / Helical rack DIN9

Gear Grinding Precision:DIN9

Modulus:2,3,4,5,6

Material:C45

Hardness:HRC50-55

Heat Treatment:Teeth induction hardening

The surface of the rack is blackened after high-frequency quenching, and the surface of the product has a high degree of rust resistance and is not easy to corrode. The teeth surface has high hardness and high wear resistance, and can be adapted to linear transmission equipment that is frequently used reciprocatingly.

Gears: We provide non-standard customization of gears

Racks and gears are available for industrial applications:

Robots automation (solution for economical racks, reliable operation and extremely long service life);

Gantry machining center (we provide large and high-precision solutions);

Laser cutting machine (high acceleration, high operation, high precision);

Aluminum profiles, woodworking machining centers (higher precision racks available to optimize your product quality);

Other fields (we provide effective solutions for the linear transmission field of various equipment);